Back

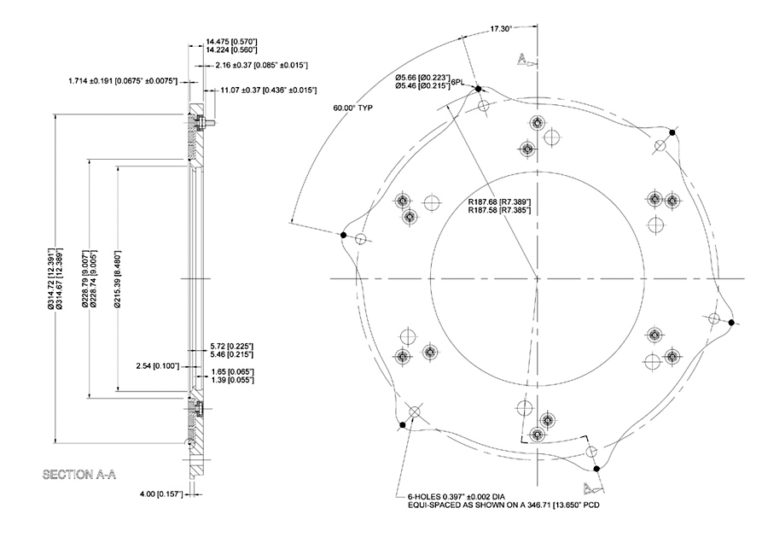

Fixed wing propeller aircraft use specialist de-icing slip rings to pass electrical power from the airframe generators to the rotating propellers These propellers are heated to avoid the build up of ice either in flight or on the ground in difficult weather conditions.

The correct choice of materials for the rings and brushes, together with a very fine surface finish on the rings themselves, ensure the optimum life of the unit in operation. The life time is generally in excess of 1500 hours at 1200 rpm – equivalent to >100 million revolutions, with only a simple maintenance operation to change the brushes and brush block.

Units are designed for each application in conjunction with the customers’

requirements.

Typically these slip rings are supplied to the Propeller system manufacturer. Moog Components pedigree extends over many years and the following programmes are examples of where our products are used:

Propeller slip rings

Fixed wing propeller aircraft use specialist de-icing slip rings to pass electrical power from the airframe generators to the rotating propellers These propellers are heated to avoid the build up of ice either in flight or on the ground in difficult weather conditions.

The correct choice of materials for the rings and brushes, together with a very fine surface finish on the rings themselves, ensure the optimum life of the unit in operation. The life time is generally in excess of 1500 hours at 1200 rpm – equivalent to >100 million revolutions, with only a simple maintenance operation to change the brushes and brush block.

Units are designed for each application in conjunction with the customers’

requirements.

Typically these slip rings are supplied to the Propeller system manufacturer. Moog Components pedigree extends over many years and the following programmes are examples of where our products are used:

- Jetstream

- Fokker 50

- SAAB 340

- Grumman

- SAAB 2000

- De Havilland Dash 8

- Lockheed Martin C130J

- ATR42

- Airbus A400M